Your basket is currently empty!

How to fit a flash steam boiler

To make your own Pop Pop Boat, we suggest using an empty sardine tin, but you can also use any other metallic container, like a drinks can, that is non-flammable. Please take extra care of sharp edges when you are cutting the material into the hull shape and drilling the holes for the boiler pipes.

Read the instructions thoroughly before starting.

POP POP BOAT ENGINE FITTING INSTRUCTIONS

- Drill two holes at the rear of your model at a slight angle – the ends of the boiler pipes must be below the water line.

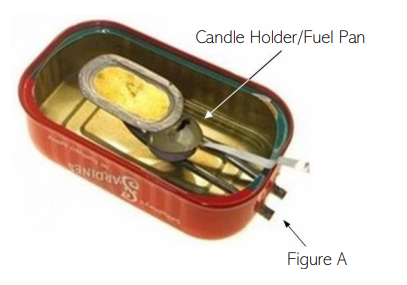

- Place the boiler into the hull and insert the two pipes through the holes at the stern. Care must be taken as the boiler is very fragile. The pipes must protrude approximately 3 – 5mm out of the back of the boat – see Figure A.

- Seal the inside of the hull around the pipes using glue or melted wax.

HOW TO START YOUR POP POP BOAT

- Using a plastic dropper, squirt water into the boats exhaust pipes until full. This is the only way water can enter the boiler. Damage may occur if the boiler is empty. Alternatively, pour water into one of exhaust pipes using a running tap or water from a jug until water flows freely from the other pipe.

- Put the boat into the water carefully, making sure that the water stays in the boiler.

- Place the candle into the holder and light the wick.

- Gently place the holder onto the runners in the boat until it is resting underneath the boiler. The ideal position is for the flame is to be central under the boiler and not directly below the two small pipes leading from the boiler.

- The water in the boiler will heat by the candle turning it into steam. The steam expands causing a “popping” noise. The steam is forced out of the exhaust pipes propelling the boat forward.

- Once the steam has left the boiler, a vacuum is created, sucking fresh water back into the boiler the process starts all over again. The noise generated – “Pop Pop!”

AFTERCARE

After using your boat, flush out the boiler with clean cold water to reduce the risk of the boiler overheating when it’s removed from the bowl or pond.

- Wipe off any excess water and carefully remove any wax deposits inside the boat.

- A small shot of light lubricating oil (e.g. WD40) into the pipes will prevent rusting.

- Gently clean under the boiler with a damp cloth to remove any soot deposits. Care should be taken at this point, as the boilers are very sensitive.

- Lightly rub the outside of the boat with a small amount of oil (e.g. WD40) on a cloth, to prevent rust forming.

- Store in a dry place – ready for the next outing!